Methods-Time Measurement {MTM}

Methods-Time Measurement (MTM) is the most established of all pre- determined motion-time systems (PMTS). The system was developed in the US. This has been the case since its publication in 1948. MTM is a worldwide phenomenon today. The MTM Association Benelux seeks to uphold the professional standards of training and research. According to the vision of Mike Maynard, who was the father of MTM. It was he who coined the phrase “MTM – First Time Right!

MTM stands for:

- Reliability

- Profitability

- Adaptability

Definition of MTM

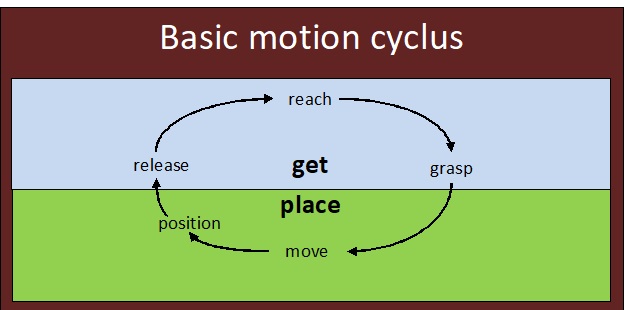

MTM is a work analysis technique. With this technique, human labour can be analysed into motions, which is necessary for the performance. Time standards have been set for the motions depending on the nature of the motions and the conditions under which they are performed.

Why MTM

MTM is a complete system to designing a productive and healthy working environment. It can be used in production, logistics, services, organisational institutions and the office. MTM is suitable for personnel planning and process management, due to its analytical methods and uniform basic performance. MTM is a globally spread and acknowledged process building block system.

- Since 1948 successfully applied,

- Pace the performance index is not necessary, so that can be fully focused on the optimal method,

- MTM in the development stage can be applied, so that costs be avoided,

- Standard time methods developed for mass manufacture up to and including single pieces,

- Methods for product development, ergonomics and visual inspection are available,

- Capacity evaluation, calculation of cost prices, calculate ideas, and so on.

Companies such as DAF Trucks, Nedcar, Xerox, Audi Group, Flex logistics, Johnson Controls, IAC, SAS, Vanderlande and others use the MTM methods.